Demand for energy storage systems (ESS) is growing hand-in-hand with increased demand for renewable energy. According to Bloomberg, demand for energy storage capacity set a record in 2023 and will continue to grow at a CAGR of 27% through 2030—more than 2.5 times the level of today. ESS are power storage systems that are often co-located with power-generation resources—frequently renewable energy-generating resources like solar or wind—where they are continually charged. Then they discharge when needed to provide electricity on demand, helping to maintain short-term power quality and provide capacity to meet fluctuating supply and demand, for example, to provide solar-generated electricity to the grid at night.

While there are a number of types of large-scale ESS—including pumped-storage hydroelectric, solar electric with thermal energy storage, or even compressed-air storage—the most common types of ESS use battery cells as the energy storage medium and are referred to as BESS. As of December 2022, about 3,612 MW of BESS capacity were located next to or close to solar photovoltaic and wind energy projects. The stored electricity that they provide helps to stabilize power grids by providing backup power when demand rises beyond generating capacity or when renewable energy generation methods cannot fully meet the demand.

Battery producers worldwide are scrambling to meet demand for BESS. And to do so, they are navigating a series of challenges, such as seeking the best solutions to meet demands for higher battery capacity, longer cycle life, greater safety against thermal events, and lower manufacturing costs. So, while cylindrical Li-ion batteries remain common in the batteries used to power vehicles, BESS developers often use pouch or prismatic battery designs because they offer greater power capacity within the same space and require less total effort to manufacture.

One of the keys to manufacturing large capacity ESS at a lower cost is the continued evolution of ultrasonic metal welding. Let’s examine how such welding can play a role in battery production.

Ultrasonic Welding’s Potential Benefits for Battery Assembly

Historically, ultrasonic metal welding has played a critical role in joining nonferrous metals like copper and aluminum in anodes, cathodes, tabs, terminals, and other battery structures. More recently, the technology has also been used successfully to join nonferrous materials to mild steels for potential use in busbars and other battery structures. Compared with traditional welding, which melts metals and can form intermetallic compounds that contribute to corrosion, ultrasonic welding uses high-frequency vibration and pressure to bond metals without melting. In its different forms, ultrasonic metal welding can be gentle enough to create strong, low-impedance electrical connections between ultra-thin metal or polymer-metal films used in current collectors. Or it can be rugged enough to bond battery-busbar assemblies or to join braided cables essential to link battery capacity to larger power-delivery systems.

Thanks to continued improvements in the design and configuration of ultrasonic welders, manufacturers can reduce weld cycle times and realize greater assembly efficiency for everything from small cells to electric vehicle (EV) batteries to BESS. For example, the Branson GMX-Micro ultrasonic welder from Emerson enables high-speed automated welding (up to 40 cycles per minute) and accommodates larger, wider assemblies typical when bonding pouch or prismatic cells.

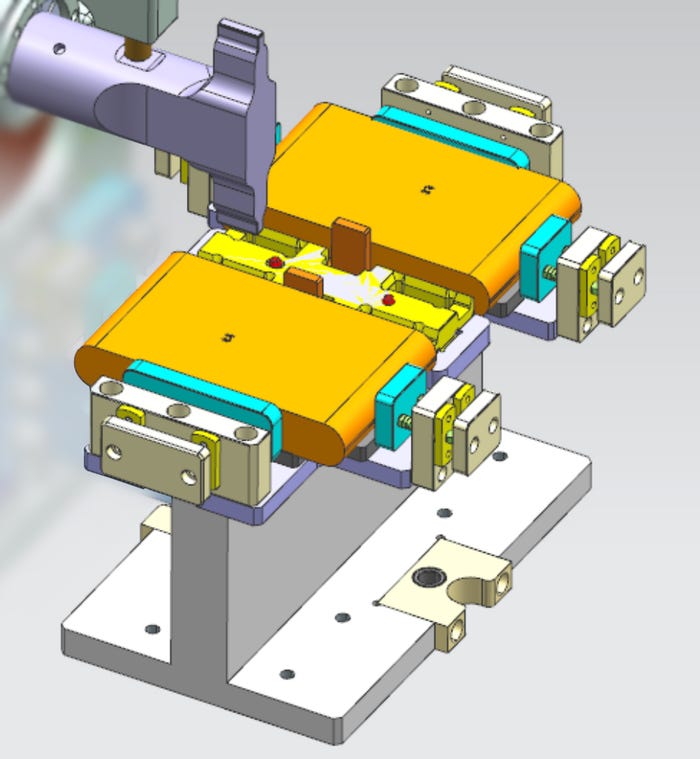

In the Branson GMX-Micro Ultrasonic Welding platform, note the hammer-shaped weld sonotrode, or “horn,” extending from the actuator. EMERSON

Welders such as the GMX-Micro use a newer welding method, referred to as “direct press,” which uses ultrasonic vibration, together with increased downforce to join thicker film structures or larger assemblies. But compared with earlier direct-press welders, they offer double the stroke length (up to 100 mm) to allow more space for:

-

Greater flexibility in moving/positioning the parts and fixturing beneath the weld horn.

-

Easier loading and unloading of parts and finished assemblies.

-

Greater flexibility in the orientation of battery modules (parallel or 90-degree offset) for compatibility with production line orientation requirements.

By taking advantage of this added room, manufacturers can undertake new and more complex welds that are essential for volume production of both BESS and EV battery assemblies. For example, the GMX-Micro now can bond the tabs of two pouch or prismatic storage cells onto a connector or busbar in a single welding cycle. Such double-sided, or “butterfly” welds, produce high-quality battery assemblies while dramatically reducing assembly time.

Close-up illustration depicts a hammer-shaped weld horn completing a “butterfly” weld. This method, which joins tabs from two batteries onto a single busbar in a single weld, improves efficiency and cuts assembly time for EV batteries and BESS. EMERSON

Through innovations like direct press and high-volume butterfly welding, ultrasonic welding technology continues to evolve, offering battery manufacturers a growing range of real and potential benefits for production of current and new-technology batteries to meet growing global demand.