A Citadel Completions team celebrations the completion of interior and exterior work on a Boeing 737 … [+]

Most people think of private jets as business aircraft from the likes of Bombardier, Cessna or Gulfstream.

But there is a booming category of much larger business jets based on airliners. Boeing Business Jets, BBJ, offers 737s on up to the BBJ777X, the longest-range business jet in the world. Airbus Corporate Jets, ACJ, offers business, private or corporate versions of the A220, A318/A319neo, A330 and A350 airliners.

For example, a narrowbody Airbus A319 airliner can seat between 110 and 160. The private version, the A319 CJ, typically holds just 19 passengers but can be configured for up to 48. The cabin is often divided into VIP quarters, with office, bathroom with stand-up shower and bed and a high-density passenger seating area for take-off and landing.

Business, government and private versions of airliners are typically not finished, or “completed,” by the aircraft manufacturer. Customers instead rely on completion companies like Citadel Completions of Lake Charles, Louisiana. Designers, suppliers and completion center collaborate with clients to create a plane’s custom interior.

Depending on the plane and the customer’s requirements, completion can cost anywhere from $5 million to $140 million or more.

A handful of big widebodies, like the ACJ350 or Boeing’s 777, are sold into the business market off the assembly line. Companies like Citadel will start designing the interiors for customers long before the plane actually rolls off.

Customers also buy airliners in the used market for conversion. They then bring them to Citadel for the design and installation of a new interior and upgrades. Citadel has refurbished planes as large as Boeing 747s. The 260,000-square-foot facility has a 10,700 ft runway to accommodate large aircraft, with multiple hangars for simultaneous projects.

A lounge in an airliner rebuilt as an executive aircraft, designed and built by Citadel Complete … [+]

Citadel can support aircraft registered worldwide, as it holds Part 145 Repair Station certifications from the FAA. While the company is best known for its interior “completions,” its skilled labor force of 220 can provide heavy maintenance, repair, and overhaul services. Such scheduled maintenance checks also help drive additional revenue and sales.

We spoke with Neil J. Boyle, SVP of Operations and General Manager for Citadel Completions, about this unique market. Boyle is a veteran of the completions industry and the US Air Force. He holds an FAA Airframe and Power plant license and a Bachelor of Science in Professional Aeronautics and a minor in Aerospace and Aviation Safety. He is certified in Lean Six Sigma and lean manufacturing.

Can you explain the completions business?

Boyle: It’s a fascinating niche business. Boeing and Airbus do not do completions on private jobs—it’s a lower volume operation than configuring commercial aircraft.

An airplane gets pulled out of the production line and comes to us without furnishing. This gives us a clean slate for interior completions. Building a “palace in the sky” is quite intense. The owners of such aircraft are very protective, very private. There’s a lot you can’t say about them publicly.

How much work does Citadel have?

Boyle: In 2022, we provided services to 51 aircraft ranging from light interiors to full cabin refurbishments plus complete cabin avionic and IFE/CMS upgrades. There are some significant refurbishments ongoing for 2023. This month, Citadel is flying to the European Business Aviation Convention and Exhibition for customer and supplier meetings.

An aircraft bathroom in a Boeing airliner converted to private use by Citadel Completions of Lake … [+]

What is the agreement with Airbus?

Boyle: In December of 2022, Airbus Corporate Jets signed a partnership with Citadel Completions LLC to enter the ACJ Services Centre Network. We provide ACJ customers capabilities like maintenance, engineering, modification and cabin-refurbishing and cabin/system upgrades.

We support ACJ customers by offering light and heavy maintenance, cabin refurbishment, and system upgrade services on A319, A320, A320neo, A330, A321neo, and A340 aircraft. Citadel provides the same services for our Boeing Business Jet customers, the B737, B747, B757, B767, and B777 aircraft family.

Are completions of widebodies the most profitable projects?

The large aircraft are the ones you really want to do business on. It’s the labor hours, the volume of work. It’s the goal to contract the large product—usually the bigger the plane, the bigger the profit.

While we do a new aircraft completion, we’re also working on all the used planes. What I want to focus on are planes like 737s, 757, 767, A320s and A330s retired from airlines to our world. We’ve got some very good projects for 2023, and room to expand.

We don’t need the new plane at the site immediately—-we know the capability, the dimensions. We can translate from design and engineering to modular construction. You take it to the airplane and it becomes plug and play. We have a partial mock-up or fake cabin in the hangar. Ideally, the new interior will be sitting, waiting for the plane.

So what do you do for these customers?

Boyle: It’s all custom.

He says Citadel can do almost anything in an aircraft interior, limited only by the client’s imagination and budget. Almost anything, that is.

A full-size shower and bathroom in a Boeing airliner converted to private use by Citadel Completions … [+]

Gas fireplaces and hot tubs are definitely in the no-fly zone. Safety is also key for TTOL—Taxi Take Off and Landing. Boyle says, “For instance, not every seat can be occupied around the conference table then.”

Boyle: We don’t use the word no. It’s always—that’s a great idea. We’ll get back to you, or let’s see what we can do!

You can use our own designer or yours. You validate whether that design can be done throughout that aircraft, considering weight, speed, cargo, fuel, and center of gravity. It sounds less complicated than it is. It can take 12-18 months to go from idea to finished design for a project. It’s a long process, sometimes eight months. Larger aircraft can be 24 months. Four or five project managers can be on the client’s team, ensuring every detail is correct.

You go room by room, put in the carpet, the ceiling. Each step is authentic down to the stitching, the piping, the embossing of seats, only ten stitches per inch; the possibilities are endless. We’ve put in 24-karat gold finishes, silk carpets, and upholstery.

We team up with leading interior designers such as Massari Design of Fano Italy, known for their design excellence in private homes, aircraft, hotels, casinos, and other world-renowned designers. We strive to involve the client before the project starts, sometimes up to a year before.

Boyle adds that Citadel isn’t just doing the interior or the paint. “We can install the satellite communications or even help with the military side on certain aircraft, such as threat detection or missile defense systems.”

A full-sized kitchen installed in an airliner converted to a private aircraft by Citadel Completions … [+]

Once you’ve designed and put in a new interior, how do you continue to profit from a completed aircraft?

RMU—refurbishment, maintenance and upgrades. Maintenance has to be done on either an hourly or calendar basis. We can do upgrades—cameras, connectivity, upgrading wiring, appliances, door latches, inflight entertainment, cabin management, lighting. And ultimately, perhaps refurbishment, removing the interior and putting a new one in.

How long does a completion take?

That’s the biggest question customers have; when can I get my airplane and travel? We have done an Airbus A320 or Boeing 737 in 8 months. We want to reduce cycle time—clients have paid significantly. As long as the design, engineering, and fabrication are completed, the turnaround time after aircraft induction is quick, pre-planning is the key.

So who are your customers?

Our clients are high-profile, discreet, and very private. We have served Presidents, Heads of State, rulers of foreign countries, private owners, family businesses, domestic and corporate agencies, half a dozen professional athletic teams.

Can you give us some names?

Personally, I never share the name of a client.

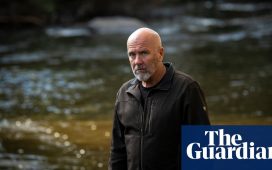

Neil J. Boyle, SVP of Operations and General Manager for Citadel Completions of Lake Charles, LA